Solution

-

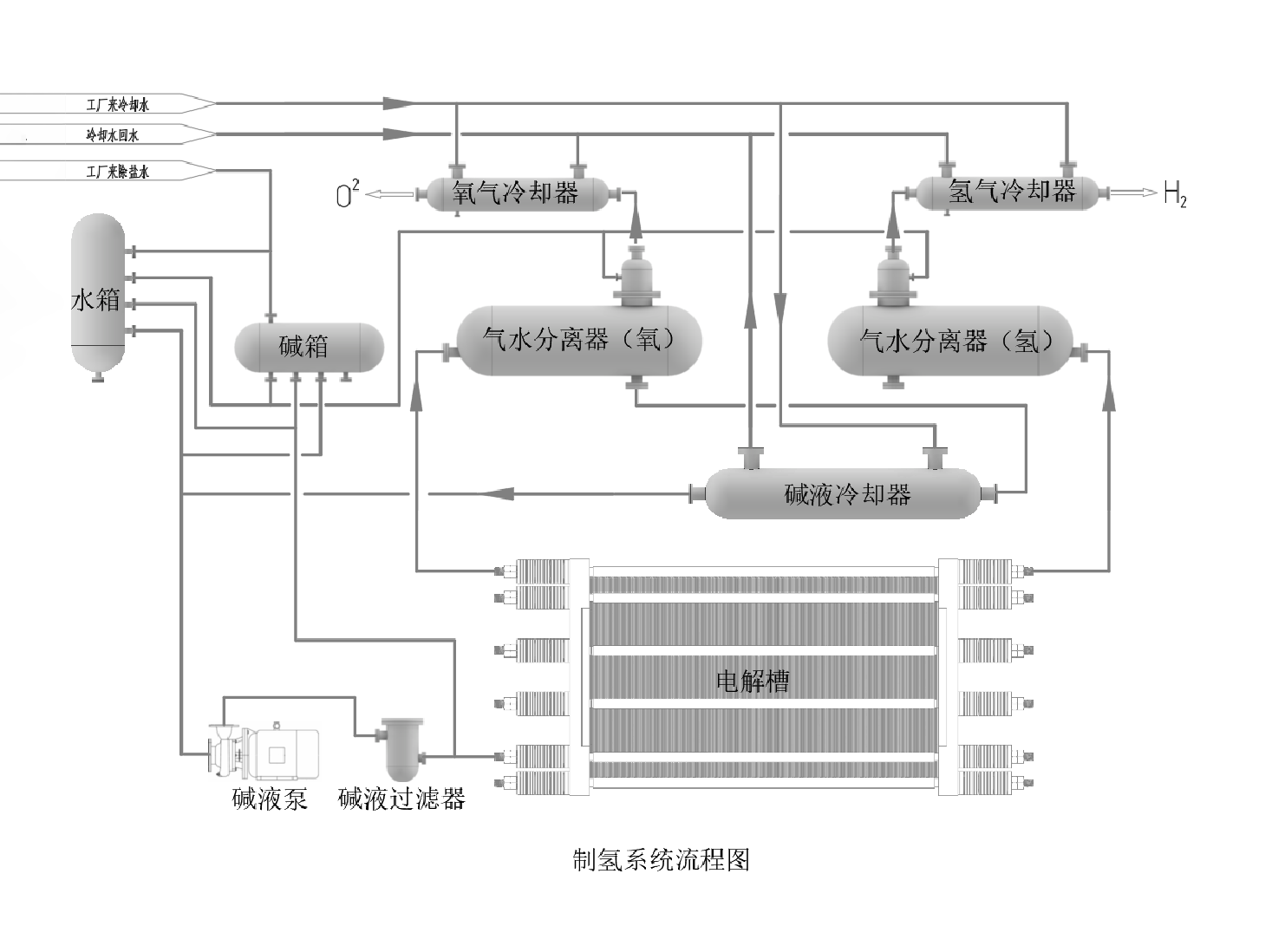

Hydrogen production system scheme

- Make the world healthier, safer, smarter, and more sustainable

-

1MW-200Nm at a photovoltaic plant in Inner Mongolia ³/ Hydro…

- In actual operation, the current density of the electrolytic cell reaches 6500A/m ², The energy consumption of the entire hydrogen production system is as low as 4.48kWh/Nm per standard cubic meter of hydrogen gas ³, After purification, the purity of the exported hydrogen gas reaches 99.9999%.

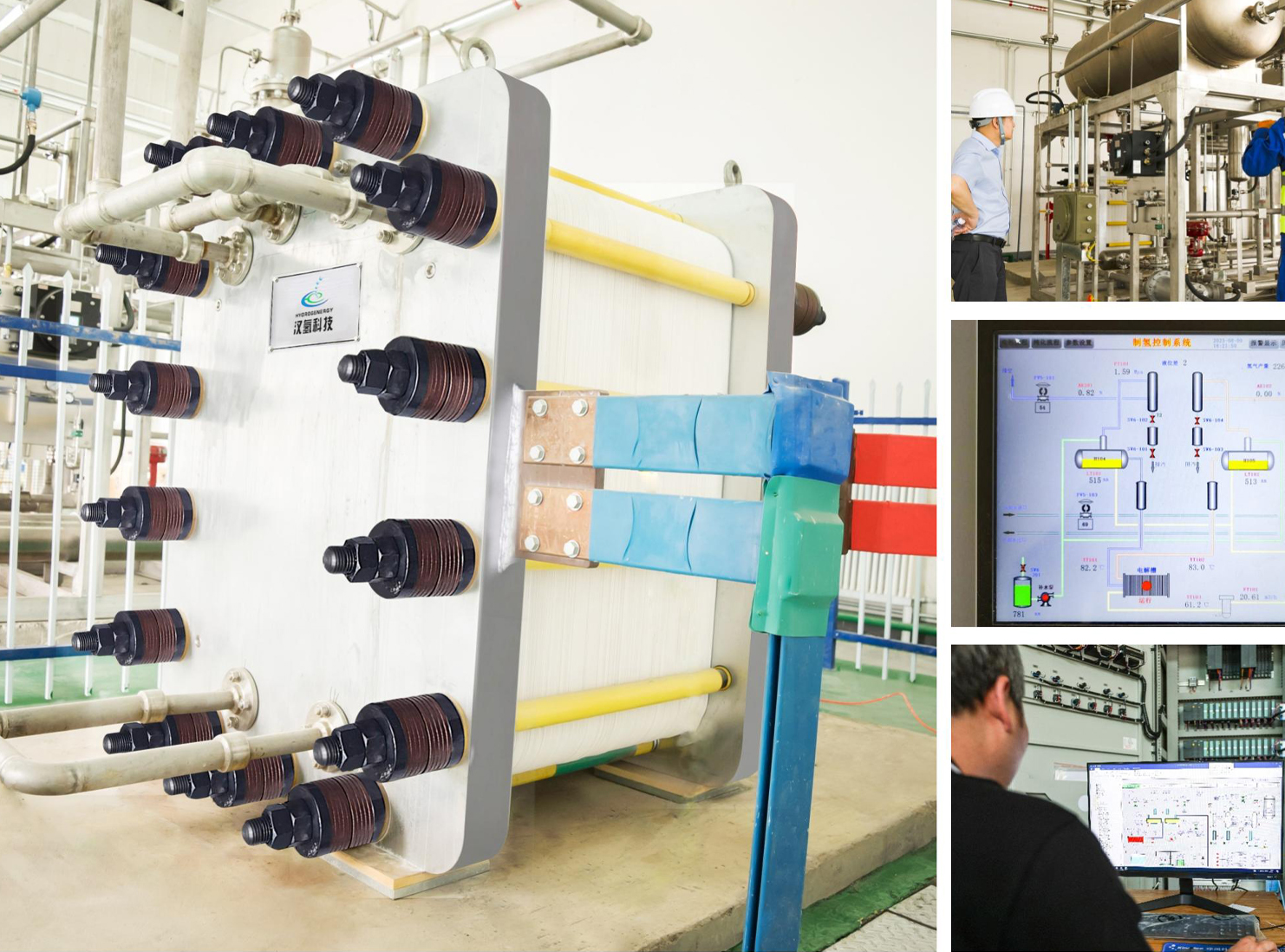

Higher current density means higher electrolysis efficiency and more compact equipment construction. The width and height of Han Hydrogen Technology's entire series of infinite frame electrolytic cells are unified in size: 1300mm × 1410mm, by changing the length of the electrolysis cell, i.e. the number of electrolysis chambers, can meet the needs of different hydrogen production capabilities.

The fast response capability of the electrolysis system: The electrolysis cell can be raised from room temperature to 50 ℃ in just 5 minutes, and the hydrogen production can reach 17ONm ³/ H; Rising from room temperature to 83 ℃ in just 10 minutes, the hydrogen production reaches 240Nm ³/ h. Exceeding rated output by 200Nm ³/ 20% of h.

Power fluctuation response: The current drops or rises by 50% within 10 seconds, and the electrolytic cell and the entire system can withstand nature. Only a corresponding decrease or increase in hydrogen output is required, resulting in stable system operation.

- In actual operation, the current density of the electrolytic cell reaches 6500A/m ², The energy consumption of the entire hydrogen production system is as low as 4.48kWh/Nm per standard cubic meter of hydrogen gas ³, After purification, the purity of the exported hydrogen gas reaches 99.9999%.

-

Comprehensive Green Hydrogen Application Solution

- Provide pre assembled modular hydrogen production units, with customized modules allowing customers to freely choose the specifications and quantity of electrolytic cells. By combining electrolytic cells with different production capacities and different quantities of modular hydrogen production units, ultra large scale hydrogen production can be achieved.

Flexibly adapting to hydrogen demand in different scenarios, the modular electrolysis device system design can achieve a million kilowatt level (i.e. GW level) installed capacity for electrolytic hydrogen production, meeting the needs of large-scale green hydrogen production.

- Provide pre assembled modular hydrogen production units, with customized modules allowing customers to freely choose the specifications and quantity of electrolytic cells. By combining electrolytic cells with different production capacities and different quantities of modular hydrogen production units, ultra large scale hydrogen production can be achieved.

-

Complete technical solution for large-scale hydrogen product…

- Design and provide various system equipment for hydrogen production plants with a hydrogen production capacity of over 100000 Nm3/h. Including large-scale transformer equipment in hydrogen production stations, large-scale IGBT rectification equipment, desalination water system, cooling water system, water electrolysis hydrogen production system, hydrogen compression system, nitrogen blowing system, drainage and sewage system, other distribution equipment, automatic control system, hydrogen transportation pipeline system, etc.